ZYD-100 Transformer Oil Two-stage Vacuum Oil Filter

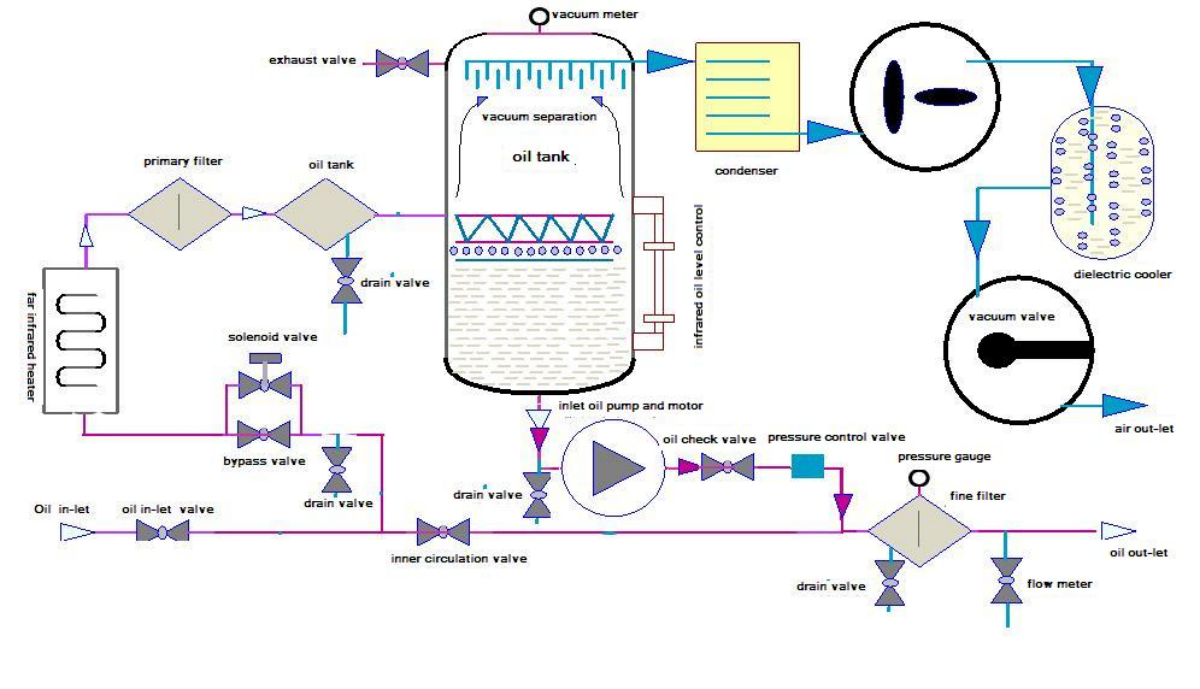

Device connection Diagram

Device consist of heating system, oil transfer system , vacuum separate system,condensation system,filtering system,control system and vacuum system.

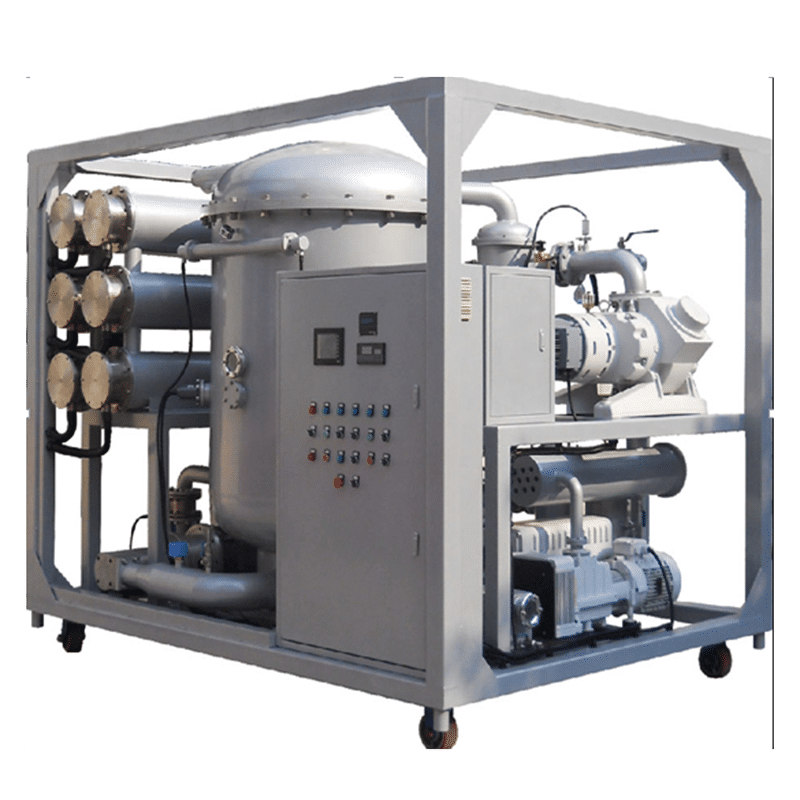

Appearance picture

| Flow | 6000L/H |

| Input voltage | AC 420V, 50HZ or 60HZ, 3P4W |

| Limited vacuum | ≤7Pa |

| Working vacuum degree | ≤133Mpa |

| Vacuum Pump lashing Velocity | ≥2000m3/h |

| Vacuum leakage | ≤11Pal/s |

| Working pressure | ≤0.5Mpa |

| Working oil temperature range | 55-95℃ |

| Thermal Power | 60KW(thermal speed from 30℃,temperature not more than 25℃ by heater, heating surface load not more than 1.2W/cm2) |

| Total Power | 68KW |

| Incoming and Outgoing Pipe Diameter | DN32 |

| Vacuum Interface Diameter | DN32 |

| Dimension | 1450mm*1250mm*1900mm |

| Device weight | 600kgs |

| Continuous working time | ≥600H |

| Work time without fault | ≥8000H |

| Work noise | ≤75dB(A) |

| Inner Circulating Oil | 6000L/H(2000-6000L/H adjustble by frequency conversion) |

| Pump head | 30m |

| Suction lift | 30m |

|

Sr. |

Item |

Index after filtering | ||

|

1 |

Moisture content(ppm): |

≤2PPM(GB/T7600) |

None(hint)(GB/T260) |

|

|

2 |

Filtering precision(um): |

front filter cartridge precision:5 µm back filter cartridge precision:1 µm |

None (GB/T511) |

|

|

3 |

oil breakdown voltage(kv)

|

75(GB/T507) |

||

|

4 |

oil dielectric loss |

≤0.05% |

||

|

5 |

Gas content in oil(%) |

≤0.1%(GB/T423) |

||

| 6 |

Acid value(mgKOHg) |

≤0.03mgKOHg |

||

| 7 | Close Flash point(℃) |

≧135℃ |

||

|

8 |

vacuum leakage(Pa.L/S) |

≤11Pa·L/S |

||

|

9 |

Gas content %(V/V) |

≤0.2% |

oil circulation through 1 time |

|

|

≤0.1% (volume ratio) |

oil circulation through 3 times |

|||

|

10 |

Moisture content(mg/L)

|

≤2.5mg/L |

oil circulation through 1 time |

|

|

≤0.4mg/L |

oil circulation through 3 times |

|||

|

11 |

breakdown voltage(kV)

|

≥65kV |

oil circulation through 1 time |

|

|

≥75kV |

oil circulation through 3 times |

|||

|

12 |

Granular (NASS1638 class) |

≤3 class |

oil circulation through 1 time |

|

|

≤2 class |

oil circulation through 3 times |

|||